Portable Visual Detection of H2O2 in Plant Samples: A Comprehensive Guide for Researchers and Scientists

This article provides a comprehensive examination of portable visual detection methods for hydrogen peroxide (H2O2) in plant samples, addressing a critical need in plant stress physiology research and drug development.

Portable Visual Detection of H2O2 in Plant Samples: A Comprehensive Guide for Researchers and Scientists

Abstract

This article provides a comprehensive examination of portable visual detection methods for hydrogen peroxide (H2O2) in plant samples, addressing a critical need in plant stress physiology research and drug development. We explore the fundamental role of H2O2 as a key biomarker for oxidative stress in plants under various environmental challenges. The content covers emerging portable sensor technologies, including innovative microneedle-based wearables and dual-functional hydrogel systems that enable real-time, on-site monitoring without complex laboratory equipment. We detail methodological considerations for sample preparation, storage optimization, and assay implementation, alongside troubleshooting common interference issues in plant matrices. The article further validates these portable approaches through comparative analysis with established laboratory techniques like eFOX and Ti(SO4)2 assays, providing researchers with reliable performance metrics and practical implementation guidelines for accurate H2O2 quantification in diverse plant systems.

Understanding H2O2 as a Critical Plant Stress Biomarker: Foundations for Detection

The Biological Significance of H2O2 in Plant Stress Responses

Hydrogen peroxide (H₂O₂) is a crucial reactive oxygen species (ROS) that plays a dual role in plant physiology, acting as both a damaging toxic compound at high concentrations and a key signaling molecule at controlled levels. As sessile organisms, plants have evolved sophisticated mechanisms to perceive and respond to various environmental stresses, with H₂O₂ emerging as a central mediator in these processes. Its relative stability compared to other ROS (lifetime of ms to s) and ability to diffuse across membranes make it an ideal signaling molecule [1] [2]. This application note explores the biological significance of H₂O₂ in plant stress responses, with particular emphasis on emerging portable detection technologies that enable real-time monitoring of this crucial signaling molecule in field conditions. Understanding H₂O₂ dynamics provides valuable insights into plant health, stress adaptation mechanisms, and development of stress-resilient crops.

H₂O₂ as a Key Signaling Molecule in Plant Stress Responses

In plant cells, H₂O₂ is continuously produced as a byproduct of aerobic metabolism in various cellular compartments, including chloroplasts, mitochondria, peroxisomes, and the apoplast [2]. Under normal physiological conditions, plants maintain H₂O₂ at non-toxic levels through the action of both enzymatic antioxidants (catalase, ascorbate peroxidase, glutathione peroxidase) and non-enzymatic antioxidants (ascorbate, glutathione, flavonoids) [2] [3]. However, when plants encounter biotic or abiotic stresses, the delicate balance between H₂O₂ production and scavenging is disrupted, leading to a rapid increase in cellular H₂O₂ concentrations known as an "oxidative burst" [2].

The dual nature of H₂O₂ is evident in its concentration-dependent effects. At low concentrations, H₂O₂ functions as a secondary messenger that modulates various stress-responsive genes and signaling pathways, including those involving mitogen-activated protein kinases (MAPKs) and calcium-dependent protein kinases (CDPKs) [3]. At higher concentrations, H₂O₂ can cause oxidative damage to cellular components and even trigger programmed cell death (PCD), which serves as a defense mechanism to limit pathogen spread [2]. This dual functionality makes precise monitoring of H₂O₂ levels critical for understanding plant stress physiology.

H₂O₂ in Abiotic Stress Responses

Plants experience various abiotic stresses, including drought, salinity, extreme temperatures, and heavy metal toxicity, all of which can induce increased H₂O₂ production. Research has demonstrated that H₂O₂ pretreatment can enhance plant tolerance to subsequent stress events through a process known as acclimation. For instance, in pepper plants (Capsicum annuum), foliar application of H₂O₂ in doses between 0 and 400 mM resulted in biostimulation of crop development and growth under low fertigation conditions [4]. Similarly, in maize leaves, H₂O₂ pretreatment significantly increased ABA content, a key hormone in stress responses [2].

Recent studies on seaweed aquaculture have highlighted the potential of H₂O₂ as a bioindicator of stress, where exposure to acute stressors led to rapid and sustained H₂O₂ concentrations orders of magnitude higher than fluctuations observed under normal diurnal cycles [5]. This suggests that monitoring H₂O₂ could serve as an early warning system for stress detection in commercial aquaculture operations.

H₂O₂ in Biotic Stress Responses

When plants encounter pathogenic organisms, H₂O₂ production is one of the earliest defense responses activated. The oxidative burst serves multiple protective functions: it directly damages invading pathogens, strengthens plant cell walls through cross-linking of structural proteins, and acts as a signaling molecule to activate additional defense mechanisms [3]. Research has shown that H₂O₂ foliar application can attenuate symptoms of pepper golden mosaic virus [4], demonstrating its practical application in managing plant diseases.

H₂O₂ also plays a crucial role in systemic acquired resistance (SAR), a long-lasting, broad-spectrum resistance that develops throughout the plant after initial pathogen exposure. Studies have revealed complex interactions between H₂O₂ and other signaling molecules, including salicylic acid, jasmonic acid, and ethylene, which collectively fine-tune plant immune responses [2]. The integration of H₂O₂ within these signaling networks enables plants to mount appropriate defenses against diverse pathogens.

Quantitative H₂O₂ Dynamics Under Stress Conditions

Table 1: H₂O₂ Concentration Changes in Response to Various Stressors

| Plant Species | Stress Condition | H₂O₂ Concentration | Detection Method | Reference |

|---|---|---|---|---|

| Capsicum annuum | H₂O₂ foliar application (0-400 mM) | Not specified (biostimulation observed) | Biochemical assays | [4] |

| Seaweed (Ulva fenestrata) | Acute stress | 710 (± 38) nM g⁻¹ FW (significantly higher than controls) | Chemical detection | [5] |

| Seaweed (Palmaria palmata) | Acute stress | 394 (± 87) nM g⁻¹ FW (significantly higher than controls) | Chemical detection | [5] |

| Arabidopsis thaliana | Control conditions (hy5 mutant) | Elevated in root apical meristem | DAB staining | [6] |

| Riparian plant species | Environmental stress monitoring | Species-specific variations | eFOX & Ti(SO₄)₂ assays | [7] |

Table 2: Comparison of H₂O₂ Detection Methods in Plant Research

| Method | Detection Principle | Sensitivity/LOD | Advantages | Limitations | |

|---|---|---|---|---|---|

| Portable Pt-Ni hydrogel sensor | Peroxidase-like & electrocatalytic activity | 0.030 μM (colorimetric), 0.15 μM (electrochemical) | Portable, excellent selectivity, long-term stability (60 days) | Requires sensor fabrication | [8] |

| DAB staining | H₂O₂-dependent brown precipitation | Not specified | Histochemical localization, relatively simple | Semi-quantitative, tissue destruction | [9] |

| roGFP2-Orp1 sensors | Genetically encoded fluorescent sensor | Not specified | Non-invasive, subcellular resolution, in vivo monitoring | Requires transgenic plants | [1] |

| eFOX assay | Ferrous oxidation by H₂O₂ | Can detect lower fluctuations than Ti(SO₄)₂ | High sensitivity, adaptable to high-throughput | Potential interference | [7] |

| Ti(SO₄)₂ assay | Titanium-H₂O₂ color complex | Less sensitive than eFOX | Accessible, simple procedure | Less sensitive than eFOX | [7] |

Signaling Pathways and Molecular Interactions

H₂O₂ mediates its effects through complex signaling networks that involve interactions with various molecular components. The MAPK cascade represents a crucial signaling pathway activated by H₂O₂ in plants. In pepper plants, combined application of H₂O₂ and acoustic frequencies (MHAF) showed synergistic effects on the relative gene expression of MAPKinases (mkk5, mpk4-1, mpk6-2), suggesting that H₂O₂ participates in the activation of these key signaling components [4].

H₂O₂ also interacts with hormonal signaling pathways. Research has revealed extensive cross-talk between H₂O₂ and plant hormones such as abscisic acid (ABA), salicylic acid (SA), and ethylene. For instance, in Arabidopsis, the transcription factor ELONGATED HYPOCOTYL 5 (HY5) promotes root growth by maintaining redox homeostasis and repressing oxidative stress response. The hy5 mutants displayed hypersensitivity to H₂O₂ and altered expression of genes involved in redox homeostasis [6]. This demonstrates how H₂O₂ signaling is integrated with developmental pathways to optimize plant growth under stress conditions.

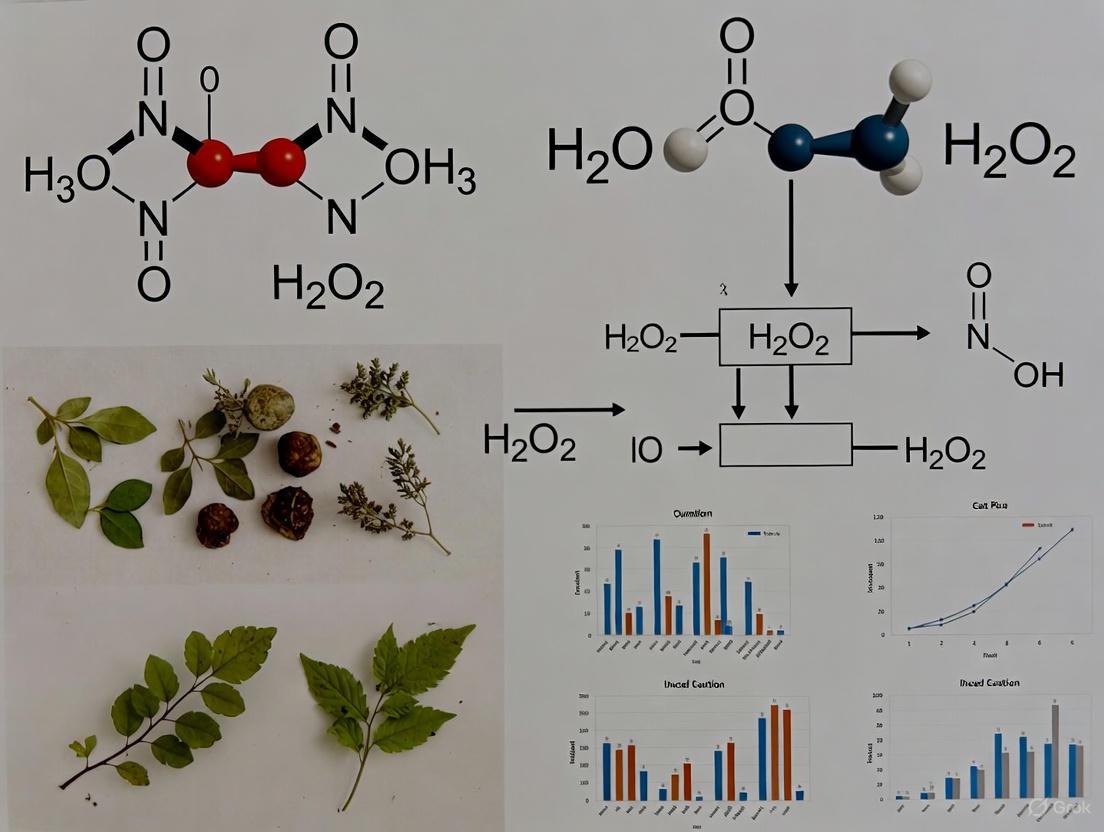

Figure 1: H₂O₂-Mediated Stress Signaling Pathways in Plants. This diagram illustrates the key signaling pathways activated by H₂O₂ in response to environmental stresses, showing the integration with MAPK cascades, calcium signaling, and hormonal networks that collectively lead to stress adaptation.

Experimental Protocols for H₂O₂ Detection and Analysis

Portable Visual and Electrochemical Detection Using Pt-Ni Hydrogels

Principle: Pt-Ni hydrogels with excellent peroxidase-like and electrocatalytic activities enable simple and sensitive H₂O₂ sensing through both colorimetric and electrochemical strategies [8].

Procedure:

- Sensor Fabrication: Synthesize Pt-Ni hydrogels via coreduction of mixed metal salt solution by sodium borohydride. Optimize Pt/Ni atomic ratios (e.g., PtNi3) for maximum catalytic activity.

- Colorimetric Detection:

- Immobilize Pt-Ni hydrogel on test paper or in solution

- Add 3,3,5,5-tetramethylbenzidine (TMB) substrate

- Expose to plant extract or monitoring environment

- Measure color change spectrophotometrically at 652 nm or visually

- Electrochemical Detection:

- Modify screen-printed electrodes with Pt-Ni hydrogel

- Connect to portable potentiostat or M5stack development board

- Measure current response at optimized potential

- Quantify H₂O₂ concentration using calibration curve

- Validation: Test sensor performance with standard H₂O₂ solutions and validate against traditional methods like ultraviolet-visible spectrophotometry [8].

Applications: This portable system has been successfully applied to detect H₂O₂ released from living cells, showing good agreement with conventional methods (1.97 μM vs. 2.08 μM for visual detection compared to UV-vis) [8].

DAB Staining for Histochemical Localization of H₂O₂

Principle: 3,3-diaminobenzidine (DAB) polymerizes in the presence of H₂O₂ and peroxidase activity to form a brown precipitate that can be visualized microscopically [9].

Procedure:

- Solution Preparation:

- Prepare fresh DAB staining solution: 50 mg DAB in 45 mL sterile H₂O

- Adjust pH to 3.0 with 0.2 M HCl to dissolve DAB

- Add 25 μL Tween 20 (0.05% v/v) and 2.5 mL 200 mM Na₂HPO₄

- Final solution: 1 mg mL⁻¹ DAB in 10 mM Na₂HPO₄

- Protect from light (wrap container in aluminum foil)

- Plant Material Preparation:

- Grow plants under controlled conditions (e.g., Arabidopsis plants for 3-4 weeks)

- Select uniform leaves from comparable developmental stages

- Apply experimental treatments as required

- Staining Protocol:

- Place leaves in 12-well microtiter plate

- Add 2 mL DAB staining solution per well

- Infiltrate leaves by gentle vacuum for 5 minutes in a dessicator

- Cover plate with foil and incubate on shaker (80-100 rpm) for 4-5 hours

- Destaining and Visualization:

- Replace DAB solution with bleaching solution (ethanol:acetic acid:glycerol = 3:1:1)

- Place in boiling water bath (~90-95°C) for 15 minutes to remove chlorophyll

- Replace with fresh bleaching solution and stand for 30 minutes

- Visualize against white background with uniform lighting [9]

Applications: This protocol has been successfully used to detect H₂O₂ accumulation in Arabidopsis leaves during biotic stress responses, such as after treatment with microbial elicitors like flg22 [9].

Non-invasive In Planta Live Measurements with roGFP-Based Sensors

Principle: Genetically encoded fluorescent sensors (roGFP2-Orp1 for H₂O₂ and Grx1-roGFP2 for glutathione redox potential) allow ratiometric measurements based on redox-sensitive changes in fluorescence [1].

Procedure:

- Plant Material: Use stable transgenic Arabidopsis lines expressing roGFP2-Orp1 or Grx1-roGFP2 targeted to specific cellular compartments.

- Microscopy Setup:

- Use stereo fluorescence microscope with appropriate filters

- Set excitation to 405 nm and 488 nm, emission to 510-530 nm

- Maintain consistent imaging parameters across experiments

- Image Acquisition:

- Image mature plants (3-4 weeks old) grown in soil or hydroponics

- Capture images before and after treatments at consistent time intervals

- Ensure non-saturating exposure conditions

- Data Analysis:

- Calculate ratio of emissions (405 nm/488 nm excitation)

- Normalize ratios to fully oxidized (10 mM H₂O₂) and reduced (10 mM DTT) controls

- Express results as degree of oxidation (%) [1]

Applications: This technique enables non-invasive monitoring of H₂O₂ dynamics and redox changes in adult plants under various stress conditions with cellular and subcellular resolution.

Figure 2: Experimental Workflow for H₂O₂ Detection in Plant Research. This diagram outlines the major methodological approaches for detecting and analyzing H₂O₂ in plant samples, highlighting the integration of portable field-based methods with laboratory techniques.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Research Reagent Solutions for H₂O₂ Studies

| Reagent/Material | Function/Application | Key Features | Examples/References |

|---|---|---|---|

| Pt-Ni hydrogels | Portable H₂O₂ sensing | Dual colorimetric & electrochemical detection, high stability (60 days) | [8] |

| DAB (3,3-diaminobenzidine) | Histochemical H₂O₂ localization | Forms brown precipitate with H₂O₂, tissue visualization | Sigma-Aldrich D8001 [9] |

| roGFP2-Orp1 sensor | Genetically encoded H₂O₂ monitoring | Ratiometric measurement, subcellular resolution, non-invasive | Arabidopsis transgenic lines [1] |

| eFOX assay reagents | Spectrophotometric H₂O₂ quantification | High sensitivity, detects lower concentration fluctuations | Modified ferrous oxidation xylenol orange [7] |

| Ti(SO₄)₂ assay reagents | Spectrophotometric H₂O₂ quantification | Accessible method, simple procedure | Titanium sulfate-based detection [7] |

| Potassium phosphate buffer | Extraction and suspension medium | Maintains pH stability during H₂O₂ extraction | 50 mM, pH 6.0 [7] |

| Polyvinylpyrrolidone (PVP) | Phenolic compound sequestration | Prevents interference from phenolic compounds during extraction | Added during tissue homogenization [7] |

The biological significance of H₂O₂ in plant stress responses extends far beyond its historical reputation as a mere toxic byproduct of metabolism. As this application note has detailed, H₂O₂ serves as a crucial signaling molecule that integrates information from various environmental stresses and coordinates appropriate physiological and molecular responses. The development of portable detection technologies, such as Pt-Ni hydrogel-based sensors and advanced genetic encoders, represents a significant advancement in our ability to monitor H₂O₂ dynamics in real-time under field conditions. These technological innovations, combined with a growing understanding of H₂O₂-mediated signaling networks, open new possibilities for improving crop stress resilience and developing effective plant health monitoring systems. As research continues to unravel the complexities of H₂O₂ signaling, the potential for practical applications in agriculture, biotechnology, and environmental monitoring continues to expand.

H2O2 as an Indicator for Drought, Pathogen, and Environmental Stress

Hydrogen peroxide (H₂O₂) has emerged as a key early signaling molecule in plant stress responses, serving as a universal indicator for abiotic and biotic pressures including drought, pathogen attack, and extreme temperatures [10]. The portable, visual detection of H₂O₂ in plant samples represents a significant advancement over traditional, destructive methods, enabling real-time monitoring of crop health. This application note details the underlying principles, quantitative data, and experimental protocols for two prominent sensing technologies: a wearable microneedle patch and a near-infrared-II (NIR-II) fluorescent nanosensor. These tools are pivotal for fundamental research on plant signaling pathways and for the development of precision agriculture solutions.

H₂O2 in Plant Stress Signaling: Core Principles and Quantitative Data

When plants encounter environmental stressors, their normal biochemical processes are disrupted, leading to the production of reactive oxygen species (ROS). Among these, H₂O₂ is a stable molecule that serves as a critical distress signal and a messenger for activating the plant's defense mechanisms [11] [10]. Its concentration in plant tissues rises rapidly in response to various stressors, making it an excellent, broad-spectrum biomarker for early stress detection, often before visible symptoms like wilting or discoloration occur [12].

The table below summarizes the quantitative relationship between specific stress agents and the resulting H₂O₂ levels in plants, as validated by recent sensing technologies.

Table 1: Quantified H₂O2 Plant Stress Responses

| Stress Agent / Type | Plant Species Studied | Key Quantitative Findings on H₂O₂ | Detection Technology |

|---|---|---|---|

| Bacterial Pathogen(Pseudomonas syringae pv. tomato DC3000) | Tobacco, Soybean [11] [10] | • Sensor current output directly correlated with H₂O₂ concentration [12].• Higher electrical signal in infected vs. healthy plants [10]. | Wearable Microneedle Sensor |

| Drought Stress | Maize [13] | • Characteristic changes in NIR water spectral patterns observed.• Patterns allowed PLS modeling to determine drought days. | NIR Spectroscopy & Aquaphotomics |

| Multiple Stressors(e.g., Heat, Cold, Salt, Pathogen) | Arabidopsis, Lettuce, Spinach, Pepper, Tobacco [14] | • NIR-II fluorescence signal activated by trace H₂O₂.• Machine learning model differentiated 4 stress types with >96.67% accuracy. | NIR-II Fluorescent Nanosensor |

Experimental Protocols for H₂O2 Detection

This section provides detailed methodologies for implementing the two primary detection platforms.

Protocol: Wearable Microneedle Sensor for H₂O2 Detection

This protocol describes the use of a biohydrogel-enabled microneedle sensor for in-situ, electrochemical detection of H₂O₂ in plant leaves [11] [10].

- Principle: The sensor consists of a flexible polymer patch with an array of gold-coated microscopic needles. A chitosan-based hydrogel coating contains an enzyme (e.g., horseradish peroxidase) that reacts with H₂O₂ to produce electrons. Reduced graphene oxide in the hydrogel facilitates electron conduction, generating an electrical current proportional to the H₂O₂ concentration [15] [16].

Workflow: The following diagram illustrates the experimental workflow and sensing mechanism.

Materials:

Step-by-Step Procedure:

- Plant Preparation: Grow plants under controlled conditions. For stress induction, inoculate a group of plants with a bacterial pathogen via leaf infiltration, while keeping a control group healthy [10].

- Sensor Application: Press the microneedle patch gently but firmly onto the underside of a leaf, ensuring the microneedle array penetrates the epidermis and makes contact with the apoplastic fluid [11] [12].

- Measurement: Allow the electrochemical reaction to proceed for under one minute. The connected electronics module will record the electrical current generated [12] [17].

- Data Collection: Record the stable current reading. Higher current values indicate higher concentrations of H₂O₂, signifying greater plant stress [12].

- Reuse: The patch can be carefully removed and reused on other leaves. The current design allows for up to nine repeated uses before the needles lose efficacy [11] [10].

Protocol: NIR-II Fluorescent Nanosensor for H₂O2 Imaging

This protocol outlines the use of a machine learning-powered, activatable NIR-II fluorescent nanosensor for non-invasive in-vivo imaging of H₂O₂ [14].

- Principle: The nanosensor is composed of NIR-II fluorophores with aggregation-induced emission (AIE) properties, co-assembled with polymetallic oxomolybdates (POMs) that act as a quencher. In the absence of H₂O₂, fluorescence is quenched ("off" state). Upon reaction with H₂O₂, the POMs are oxidized, their quenching effect is diminished, and a bright NIR-II fluorescence is activated ("on" state) [14].

Workflow: The diagram below visualizes the nanosensor's activation mechanism and imaging process.

Materials:

Step-by-Step Procedure:

- Sensor Infiltration: Gently infiltrate the nanosensor solution into the abaxial (lower) side of a plant leaf using a syringe [14].

- Stress Application: Expose the plant to a specific stressor (e.g., drought, cold, salt, or pathogen). A non-treated control plant is recommended.

- NIR-II Imaging: Place the plant under the NIR-II imaging system. Illuminate with the appropriate laser and capture fluorescence images over time. The activation of the NIR-II signal indicates the presence and location of H₂O₂ [14].

- Data Processing with Machine Learning: Use a pre-trained machine learning model to analyze the fluorescence patterns. The model can accurately differentiate between types of stress based on the spatiotemporal H₂O₂ signature [14].

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents and Materials for H₂O2 Sensing

| Item | Function / Description | Key Feature |

|---|---|---|

| Chitosan-based Hydrogel | Biocompatible matrix for the microneedle sensor; contains H₂O₂-reactive enzyme (e.g., horseradish peroxidase) and electron mediator (reduced graphene oxide) [11] [16]. | Enables conversion of chemical signal (H₂O₂) to electrical current. |

| Gold-coated Microneedles | Micro-scale needles on a flexible patch that penetrate the plant leaf epidermis to access apoplastic fluid with minimal damage [11] [15]. | Allows in-situ, real-time measurement without major tissue disruption. |

| AIE1035NPs@Mo/Cu-POM Nanosensor | A "turn-on" NIR-II fluorescent probe for H₂O₂. The Mo/Cu-POM quencher is highly selective for H₂O₂ over other ROS [14]. | Provides high-contrast, non-destructive imaging deep within tissue, avoiding chlorophyll autofluorescence. |

| NIR-II Imaging System | A microscopy or macroscopic system for detecting fluorescence in the 1000-1700 nm range [14]. | Enables high-resolution, real-time visualization of H₂O₂ dynamics in living plants. |

Data Analysis and Integration

For the microneedle sensor, data analysis is straightforward: the magnitude of the electrical current is directly proportional to the concentration of H₂O₂ at the measurement site [12]. This provides a quantitative, single-point measurement.

For the NIR-II nanosensor, data analysis is more complex and powerful. The fluorescence signals captured by the imaging system serve as input for a machine learning model. This model can be trained to not only confirm the presence of stress but also to classify the specific type of stress (e.g., drought vs. pathogen) with high accuracy (>96.67%), based on the unique H₂O₂ signature elicited by each stressor [14]. This transforms raw optical data into actionable diagnostic information.

Current Market Trends and Growth in Portable Detection Technologies

The accurate, on-site detection of hydrogen peroxide (H₂O₂) has become a critical capability across numerous scientific and industrial fields. In plant science research, monitoring H₂O₂ is particularly essential as it acts as a key signaling molecule in plant growth, development, and stress responses [18] [19]. Traditional analytical methods, such as titration and laboratory-based spectrophotometry, are often ill-suited for field-deployable or rapid analysis, creating a demand for portable, sensitive, and user-friendly technologies [8] [20]. The market for these portable detectors is experiencing significant growth, driven by advancements in materials science, a push towards automation, and increasingly stringent safety regulations across the globe [21].

This growth is characterized by several key trends: the development of non-enzymatic sensors using stable nanozymes and catalytic nanomaterials, the miniaturization and integration of electrochemical systems, the emergence of sophisticated optical and fluorescence-based probes, and the connectivity of devices with the Internet of Things (IoT) for real-time data monitoring [8] [21] [19]. The ASSURED criteria (Affordable, Sensitive, Specific, User-friendly, Rapid and Robust, Equipment-free, and Delivered to those who need it) established by the World Health Organization provide a framework for the ideal attributes of these rapid tests, further guiding their development in both academic and commercial settings [22]. This application note details the current market landscape and provides detailed protocols for the portable visual and electrochemical detection of H₂O₂, with a specific focus on applications for plant researchers.

The global hydrogen peroxide detector market is shaped by several powerful drivers. An increased focus on workplace safety and stringent government regulations for handling hazardous chemicals is a primary factor [21]. Furthermore, the widespread use of H₂O₂ in sterilization processes within the healthcare and food processing industries, and the need to monitor its concentration accurately, fuels market growth. Technological evolution continues to revolutionize the field, with several key trends emerging:

- Miniaturization and Portability: There is a strong shift towards compact, handheld devices that enable on-the-spot analysis, moving away from traditional centralized laboratory testing [22] [21].

- Non-Enzymatic Sensors: To overcome the limitations of natural enzymes—such as high cost, fragility, and limited stability—research and development have heavily focused on robust nanozymes and electrocatalytic nanomaterials. Metal-based hydrogels and doped metal oxides are prominent examples of these stable alternatives [8] [20].

- IoT and Smart Sensors: The integration of detectors with IoT platforms allows for real-time monitoring, data logging, and remote surveillance, which is crucial for industrial safety and automated quality control [21].

- Multi-Modal Detection: Advanced platforms now combine multiple detection techniques (e.g., visual and electrochemical) on a single device, providing flexibility and validation through complementary data [8].

The market exhibits distinct regional variations. North America is a mature market characterized by high industrial safety standards and robust regulatory frameworks from agencies like OSHA and the EPA [21]. Europe shows similar rigor, with growth influenced by EU chemical safety standards and a strong emphasis on environmental sustainability [21]. The Asia-Pacific region is witnessing the most rapid growth, driven by rapid industrialization in the chemical and pharmaceutical sectors and government-led initiatives to enhance workplace safety infrastructure [21].

Table 1: Key Market Drivers and Trends in Portable H₂O₂ Detection

| Factor | Description | Impact on Market |

|---|---|---|

| Key Drivers | Stringent safety regulations, growing use in healthcare sterilization, expansion of chemical processing industries in Asia-Pacific. | Propels adoption across pharmaceuticals, food & beverage, and water treatment sectors [21]. |

| Emerging Trends | Proliferation of non-enzymatic sensors, integration with IoT and smart factories, development of multi-gas/analyte portable devices. | Enhances accuracy, usability, and functionality of detectors, enabling predictive maintenance and remote monitoring [21]. |

| Regional Growth | North America and Europe are driven by regulations; Asia-Pacific growth is fueled by industrial expansion and infrastructure upgrades. | Creates a dynamic global landscape with varied opportunities for detector manufacturers [21]. |

Quantitative Performance of Recent Portable H₂O₂ Sensors

Recent advancements in material science have led to significant improvements in the performance of portable H₂O₂ sensors. The tables below summarize the analytical figures of merit for selected technologies featured in this note, highlighting their relevance to portable and on-site applications.

Table 2: Performance Metrics of Featured Electrochemical Sensors

| Sensor Platform | Detection Technique | Linear Range | Limit of Detection (LOD) | Sensitivity | Reference |

|---|---|---|---|---|---|

| Ag-CeO₂/Ag₂O/GCE | Amperometry | 1 × 10⁻⁸ M – 0.5 × 10⁻³ M | 6.34 µM | 2.728 µA cm⁻² µM⁻¹ | [20] |

| Pt-Ni Hydrogel/SPE | Amperometry | 0.50 µM – 5.0 mM | 0.15 µM | Not Specified | [8] |

Table 3: Performance Metrics of Featured Colorimetric & Optical Sensors

| Sensor Platform | Detection Technique | Analysis Time | Limit of Detection (LOD) | Key Feature | Reference |

|---|---|---|---|---|---|

| Pt-Ni Hydrogel Test Paper | Colorimetric (TMB oxidation) | < 3 minutes | 0.030 µM | Portable visual analysis with a development board | [8] |

| Small-Molecule Fluorescent Probes | Fluorescence Imaging | Real-time (Varies) | Nanomolar (10⁻⁹ M) range | Capable of subcellular localization and ratiometric measurement | [18] [19] |

Experimental Protocols for Portable H₂O₂ Detection

This section provides detailed methodologies for implementing two prominent portable detection strategies.

Protocol: Colorimetric Detection using Pt-Ni Hydrogel Test Paper

This protocol describes the fabrication and use of a portable, low-cost test paper for the visual and quantitative detection of H₂O₂, ideal for rapid screening in plant tissue extracts [8].

Research Reagent Solutions

| Item | Function / Description |

|---|---|

| Pt-Ni Hydrogel | Peroxidase-like nanozyme; catalyzes the color-producing reaction. |

| TMB Solution | Chromogenic substrate (3,3',5,5'-Tetramethylbenzidine); turns blue upon oxidation. |

| H₂O₂ Standards | A series of known concentrations for calibration. |

| Buffer (e.g., Acetate) | Provides optimal pH ( ~4.0) for the peroxidase-mimicking reaction. |

| M5Stack Development Board | Portable, programmable hardware for capturing and analyzing color intensity. |

| Filter Paper or PVDF Membrane | Solid support for immobilizing the Pt-Ni hydrogel. |

Procedure

- Synthesis of Pt-Ni Hydrogel: Prepare the PtNi₃ hydrogel by a rapid co-reduction method. Mix aqueous solutions of H₂PtCl₆ and NiCl₂. Under vigorous stirring, rapidly add a freshly prepared ice-cold NaBH₄ solution. The formation of a black hydrogel will occur instantly. Age the gel for several hours, then purify via dialysis [8].

- Test Paper Fabrication: Dilute the purified Pt-Ni hydrogel suspension and deposit a precise volume (e.g., 5 µL) onto a defined area of filter paper. Allow the paper to dry completely at room temperature.

- Sample Preparation: For plant samples, homogenize tissue in an appropriate buffer (e.g., phosphate buffer, pH 6.0-7.0) and centrifuge to obtain a clear supernatant.

- Colorimetric Reaction:

- Apply a fixed volume (e.g., 50 µL) of the standard or plant sample extract onto the Pt-Ni hydrogel spot on the test paper.

- Immediately add an equal volume of TMB solution.

- Allow the reaction to proceed for 3 minutes at room temperature for full color development.

- Detection and Data Acquisition:

- For qualitative analysis, compare the developed blue color against a standard reference chart.

- For quantitative analysis, use the M5Stack development board equipped with a color sensor. Place the reacted test paper under the sensor and record the RGB values, focusing on the Blue channel intensity decrease or the overall grayscale value.

Protocol: Electrochemical Detection using a Modified Screen-Printed Electrode (SPE)

This protocol outlines the procedure for sensitive and selective amperometric detection of H₂O₂ using a modified SPE, suitable for quantifying H₂O₂ in complex plant matrices.

Research Reagent Solutions

| Item | Function / Description |

|---|---|

| Ag-Doped CeO₂/Ag₂O Nanocomposite | Electrocatalyst; enhances electron transfer and provides active sites for H₂O₂ oxidation. |

| Screen-Printed Electrode (SPE) | Disposable, portable three-electrode system (Working, Counter, Reference). |

| Phosphate Buffered Saline (PBS) | Electrolyte solution for maintaining stable pH and ionic strength. |

| Portable Potentiostat | Compact electronic instrument for applying potential and measuring current. |

Procedure

- Synthesis of Ag-Doped CeO₂/Ag₂O Nanocomposite: Use a chemical co-precipitation method. Dissolve Ce(NO₃)₃·6H₂O and AgNO₃ in deionized water with Polyvinylpyrrolidone (PVP) as a capping agent. Gradually add NaOH solution under constant stirring. Collect the precipitate, wash thoroughly, and dry at 160°C for 12 hours [20].

- Electrode Modification:

- Prepare a catalyst ink by dispersing 5 mg of the Ag-CeO₂/Ag₂O nanocomposite in 1 mL of deionized water via sonication for 30 minutes.

- Drop-cast a precise volume (e.g., 5-10 µL) of the ink onto the working electrode surface of a clean SPE.

- Allow the electrode to dry at room temperature completely.

- Amperometric Measurement:

- Connect the modified SPE to the portable potentiostat.

- Immerse the electrode in a stirred cell containing PBS (0.1 M, pH 7.4) and apply a constant working potential (e.g., +0.4 V vs. Ag/AgCl reference on the SPE).

- Once a stable baseline current is established, successively add known aliquots of H₂O₂ standard solution or prepared plant sample into the cell.

- Record the steady-state current response after each addition.

Advanced Detection: Fluorescence Probes for Plant Science

Beyond portable colorimetric and electrochemical sensors, small-molecule fluorescent probes represent a powerful tool for fundamental plant biology research, allowing for real-time, non-invasive imaging of H₂O₂ dynamics in vivo [18].

The evolution of these probes has progressed from simple turn-on sensors to advanced systems incorporating nanoparticles, ratiometric measurement, and AI-enhanced analysis [19]. Key mechanisms include:

- Turn-On Probes: Typically consist of a fluorophore whose fluorescence is quenched by a H₂O₂-reactive group (e.g., a boronic ester). The reaction with H₂O₂ removes the quenching group, restoring fluorescence [18] [19].

- Ratiometric Probes: Provide a self-calibrating measurement by emitting fluorescence at two different wavelengths. The ratio of these emissions changes with H₂O₂ concentration, minimizing artifacts from probe concentration, instrument efficiency, or environmental factors [18].

- Near-Infrared (NIR) Probes: Offer deeper tissue penetration and reduced background autofluorescence from plant tissues, making them superior for imaging whole leaves or roots [18] [19].

Application Protocol (Conceptual): To monitor H₂O₂ bursts during a pathogen challenge in Arabidopsis leaves, a researcher would infiltrate a solution of a H₂O₂-specific fluorescent probe (e.g., a boronate-based probe like Peroxyfluor-6) into the leaf mesophyll. After a brief incubation, the leaf would be imaged using a confocal or fluorescence microscope. The increase in fluorescence intensity over time, particularly around the sites of infection, can be quantified to reveal the spatial and temporal dynamics of the oxidative burst.

Portable detection technologies for H₂O₂ have matured into sensitive, reliable, and accessible tools that are revolutionizing how researchers monitor this critical analyte in plant systems. The convergence of nanotechnology, materials science, and electronics has enabled the development of devices that meet the ASSURED criteria, making precise analysis possible outside the traditional laboratory [22] [8].

Future directions point towards even greater integration and intelligence. The combination of multiple detection modalities (e.g., electrochemical and fluorescence) on a single, miniaturized lab-on-a-chip platform is a key goal [23]. Furthermore, the integration of artificial intelligence (AI) and machine learning for data analysis will enable real-time interpretation of complex signals, pattern recognition in stress responses, and predictive diagnostics in plant health [19]. For the plant scientist, these advancements will provide an increasingly powerful "toolkit" to unravel the complex roles of H₂O₂ in plant physiology and stress acclimation with unprecedented clarity and ease.

Key Advantages of Portable vs. Traditional Laboratory Detection Methods

The accurate detection of hydrogen peroxide (H₂O₂) is crucial in plant science research, where it functions as a key signaling molecule in plant development, stress responses, and defense pathways [24] [25]. The choice of detection methodology significantly impacts the quality, speed, and applicability of research findings. This application note provides a structured comparison between portable and traditional laboratory detection methods, framed within the context of H₂O₂ analysis in plant samples. It offers detailed experimental protocols to guide researchers in selecting and implementing the most appropriate analytical strategy for their specific needs, from field-based rapid screening to high-precision laboratory quantification.

Comparative Analysis: Portable vs. Laboratory-Based Detection

The decision to use portable or laboratory-based detection hinges on the experimental requirements for speed, precision, and context of the measurement. The table below summarizes the core advantages and limitations of each approach.

Table 1: Key Advantages and Disadvantages of Portable and Laboratory-Based H₂O₂ Detection Methods

| Feature | Portable Analysis | Traditional Laboratory Analysis |

|---|---|---|

| Analysis Speed | Immediate results (seconds to minutes), enabling on-the-spot decision-making [26] | Time-consuming (hours to days), involving sample transport, preparation, and queuing [26] |

| Cost Implications | Cost-effective; reduces or eliminates sample transport and lab fees [26] | Higher cost; involves equipment, technician time, and sample transport [26] |

| Operational Context | Ideal for fieldwork; versatile for use in remote locations, greenhouses, or on the plant itself [27] [26] | Restricted to lab; requires samples to be transported from the site, risking degradation [26] |

| Data Precision & Comprehensiveness | Lower precision; may not match lab-equipment sensitivity. Restricted testing range [26] | High accuracy and precision. Can conduct a wider range of tests for more detailed analysis [26] |

| Expertise & Error Potential | Potential for operator error due to field conditions and varying user skill levels [26] | Standardized processes performed by trained professionals, ensuring consistency [26] |

| Key Technological Examples | Smartphone-based colorimeters [28], portable electrochemical sensors [29], flexible film sensors [27] | Ultraviolet-visible (UV-Vis) spectrophotometry [29], high-performance liquid chromatography (HPLC) [25] |

The performance of modern portable sensors for H₂O₂ detection is increasingly competitive. The following table quantifies the capabilities of specific portable sensing technologies as reported in recent literature.

Table 2: Performance Metrics of Recent Portable H₂O₂ Detection Technologies

| Sensor Platform / Technology | Detection Limit | Linear Range | Analysis Time / Key Feature | Ref. |

|---|---|---|---|---|

| Portable Electrochemical Sensor (Pt-Ni Hydrogel) | 0.15 μM | 0.50 μM – 5.0 mM | Used with a portable electrochemical station for cell sample analysis | [29] |

| Flexible Ratiometric Film Sensor (AIE-featured) | 7 ppb (for vapor) | N/R | Visual and ratiometric fluorescence detection; also possesses antibacterial properties | [27] |

| Smartphone-assisted Ratiometric Fluorescent Sensor | 23.08 nM | 0.08 - 50 μM | On-spot detection in food samples (e.g., milk, chicken wings) | [28] |

| Colorimetric Nanozyme Sensor (MOF-based) | 0.28 μM | 1 - 100 μM | Dual-mode colorimetric and fluorescent detection with a 3D-printed device | [24] |

| Fluorescent Probe (DN-H2O2) | 3.8 μM | N/R | Wide pH range (5.2-11.1) detection; applicable to multiple food matrices | [25] |

Experimental Protocols

Protocol: On-Site H₂O₂ Detection in Plant Leaf Tissue Using a Portable Smartphone-Based System

This protocol leverages a ratiometric fluorescent sensor and a smartphone for rapid, on-site quantification of H₂O₂ in plant leaves, ideal for stress response studies.

I. Research Reagent Solutions

Table 3: Essential Materials and Reagents

| Item | Function / Description |

|---|---|

| Colorimetric/Fluorescent Probe (e.g., HC [28] or DN-H2O2 [25]) | The molecular recognition element that selectively reacts with H₂O₂, producing a measurable color or fluorescence change. |

| Buffer Solution (e.g., 10 mM Potassium Phosphate Buffer, pH 7.4) | Provides a stable and physiologically relevant pH environment for the sensing reaction. |

| Portable UV Flashlight (365 nm) | Excites the fluorescent probe for visual or smartphone-camera-based detection. |

| Smartphone with Color Picker App | Acts as the detector for capturing color (RGB) or fluorescence intensity values from the sensor. |

| 3D-Printed Portable Detection Device (Optional) | A custom chamber that holds the sample and provides consistent LED lighting (daylight and UV) to minimize ambient light interference [24]. |

II. Workflow

III. Step-by-Step Procedure

- Sample Preparation: Harvest a fresh leaf disc (e.g., 100 mg) from the plant of interest. Immediately homogenize it in 1 mL of ice-cold potassium phosphate buffer (10 mM, pH 7.4) using a portable mini-homogenizer. Centrifuge the homogenate at ~10,000 rpm for 5 minutes using a portable centrifuge to pellet cellular debris. Collect the clear supernatant [28] [25].

- Sensing Reaction: Mix 100 μL of the supernatant with an equal volume of the probe solution (e.g., HC or DN-H2O2 at a defined concentration in the same buffer) in a small vial or a multi-well plate compatible with the detection device. Incubate the mixture for 20 minutes in the dark at room temperature to allow the reaction between H₂O₂ and the probe to complete [28] [25].

- Signal Acquisition: Transfer the reacted mixture to the sample holder of the 3D-printed portable device. Illuminate the sample with the integrated UV LED (365 nm). Using a smartphone mounted in a fixed position, capture an image of the emitted fluorescence under controlled conditions [28] [24].

- Data Quantification: Use a color picker or image analysis application on the smartphone to measure the RGB values or the fluorescence intensity of the solution. For ratiometric probes, calculate the intensity ratio of two emission channels (e.g., red/green). Determine the H₂O₂ concentration by interpolating the measured value (RGB value or ratio) against a calibration curve prepared with known H₂O₂ standards analyzed under identical conditions [28] [24].

Protocol: Laboratory-Based Validation of H₂O₂ Using UV-Vis Spectrophotometry

This protocol describes a traditional lab method for high-precision, high-sensitivity quantification of H₂O₂ in plant extracts, suitable for validation of portable sensor data.

I. Workflow

II. Step-by-Step Procedure

- Sample Preparation: Precisely weigh a frozen plant tissue sample (e.g., 500 mg). Homogenize it in 5 mL of a degassed, ice-cold phosphate buffer (50 mM, pH 7.0) in an ice bath to minimize H₂O₂ degradation. Centrifuge the homogenate at 12,000 × g for 15 minutes at 4°C. Carefully collect the supernatant for analysis [29].

- Colorimetric Reaction: Prepare a reaction mixture in a 1 mL cuvette containing 500 μL of sodium acetate buffer (0.2 M, pH 4.0), 200 μL of the plant extract supernatant, 200 μL of TMB solution (e.g., 2 mM), and 100 μL of a nanozyme catalyst (e.g., Pt-Ni hydrogel [29] or NH2-UiO-67(Zr/Cu) [24]). Mix thoroughly and incubate at 37°C for a fixed time (e.g., 10 minutes) for the blue-colored product (oxTMB) to develop.

- Absorbance Measurement: Place the cuvette in a UV-Vis spectrophotometer. Measure the absorbance of the solution at 652 nm against a reagent blank (containing all components except the plant extract) [29].

- Quantification: Prepare a standard curve by repeating the colorimetric reaction with a series of known H₂O₂ concentrations (e.g., 0, 5, 10, 20, 50 μM). Plot absorbance at 652 nm versus H₂O₂ concentration. Use the linear regression equation from this standard curve to calculate the precise concentration of H₂O₂ in the plant extract samples.

The Scientist's Toolkit: Key Research Reagent Solutions

The advancement of H₂O₂ detection relies on innovative materials and reagents. The following table details key components used in modern sensing strategies.

Table 4: Key Reagent Solutions for H₂O₂ Detection

| Research Reagent | Function in H₂O₂ Detection |

|---|---|

| Nanozymes (e.g., Pt-Ni Hydrogels [29], MOFs like NH2-UiO-67(Zr/Cu) [24]) | Stable, synthetic materials that mimic the catalytic activity of natural peroxidases, oxidizing chromogenic substrates like TMB in the presence of H₂O₂. They offer superior stability and lower cost than natural enzymes. |

| Chromogenic Substrates (e.g., TMB - 3,3',5,5'-Tetramethylbenzidine [29] [24]) | Colorless substrates that are oxidized by peroxidases (or nanozymes) in the presence of H₂O₂ to form a blue-colored product (oxTMB), enabling simple colorimetric readout. |

| AIE-Featured Materials (Aggregation-Induced Emission) [27] | Fluorophores that exhibit strong emission in their aggregated or solid state, overcoming the common problem of aggregation-caused quenching. They are ideal for constructing robust solid-state or film-based sensors. |

| Ratiometric Fluorescent Probes (e.g., HC [28]) | Probes that display a shift in fluorescence emission at two distinct wavelengths upon reaction with H₂O₂. This built-in self-calibration corrects for environmental variables and improves quantification accuracy. |

| Metal-Organic Frameworks (MOFs) [24] | Highly porous, crystalline materials with large surface areas. They can be engineered to encapsulate catalytic metals (nanozymes) or fluorophores, creating highly sensitive and selective composite sensors. |

Implementing Portable H2O2 Detection: Technologies and Practical Applications

The real-time monitoring of hydrogen peroxide (H₂O₂) in biological systems is crucial for understanding stress signaling, disease progression, and cellular communication. In plants, H₂O₂ serves as a key early warning signal for biotic and abiotic stress, triggering defense mechanisms long before visible symptoms appear [30] [12]. Traditional detection methods like histological staining, fluorescence assays, and chromatography are often time-consuming, require destructive sampling, and rely on complex laboratory instrumentation, making them unsuitable for rapid, in-field analysis [30] [31]. Recent advancements in portable sensor technology have overcome these limitations through the development of minimally invasive microneedle wearables and highly sensitive hydrogel systems. These platforms enable direct, in situ measurement of H₂O₂ with remarkable sensitivity, speed, and cost-effectiveness, opening new frontiers in precision agriculture, biomedical research, and drug development [30] [32] [12]. This document provides application notes and experimental protocols for the implementation of these emerging technologies within the context of portable visual detection of H₂O₂ in plant samples.

Emerging portable H₂O₂ sensors primarily utilize electrochemical and colorimetric detection principles, integrated into two dominant platform types: microneedle-based wearables and hydrogel-based systems. The following table summarizes the performance characteristics of recently developed technologies.

Table 1: Performance Comparison of Emerging Portable H₂O₂ Sensor Technologies

| Technology Platform | Detection Mechanism | Linear Range | Detection Limit | Response Time | Key Advantages |

|---|---|---|---|---|---|

| Biohydrogel-Enabled Microneedle Sensor [30] [33] | Electrochemical (Chronoamperometry) | 0.1–4500 μM | 0.06 μM | ~1 minute | In-situ measurement in leaves, high sensitivity, biocompatible |

| Pt-Ni Hydrogel Sensor [8] | Colorimetric | 0.10 μM–10.0 mM | 0.030 μM | <3 minutes | Dual visual/electrochemical readout, high stability (60 days) |

| Pt-Ni Hydrogel Sensor [8] | Electrochemical | 0.50 μM–5.0 mM | 0.15 μM | N/A | Portable reader, excellent selectivity, wide linear range |

| 3D-Printed Hollow Microneedle Device [31] | Electrochemical | Characterized for H₂O₂ | Characterized for H₂O₂ | N/A | Low-cost (<€1 per device), mass-producible, extracts apoplast fluid |

| 2D Photonic Crystal Hydrogel [34] | Colorimetric (Structural Color) | Not Specified | 8.8 μM | N/A | Label-free, naked-eye detection, vivid color change |

Detailed Experimental Protocols

Protocol: Fabrication and Application of a Biohydrogel-Enabled Microneedle Sensor for In-Situ H₂O₂ Monitoring in Plants

This protocol details the construction of a wearable microneedle sensor functionalized with an HRP/Cs-rGO biohydrogel for direct detection of H₂O₂ in plant leaves [30].

Reagents and Materials

- Chitosan (Cs): Low molecular weight, from Sigma-Aldrich.

- Graphite Powder: For synthesis of graphene oxide (GO).

- Horseradish Peroxidase (HRP): Enzyme, purchased from Sigma-Aldrich.

- Glutaraldehyde (GA) Solution: (1%) as a crosslinking agent.

- Phosphate-Buffered Saline (PBS): (10 mM, pH 7.4).

- Microneedle Array Template: e.g., polymer-based array.

- Gold Sputtering System: For electrode coating.

Step-by-Step Procedure

Part A: Synthesis of HRP/Cs-rGO Biohydrogel

- Prepare Cs Solution: Dissolve low molecular weight chitosan in a 0.5% aqueous acetic acid solution. Stir at 500 rpm for 12 hours at 25°C until fully dissolved.

- Synthesize rGO: Prepare reduced graphene oxide (rGO) from graphite powder using a modified Hummer's method [30].

- Prepare rGO Dispersion: Create an aqueous dispersion of rGO at a concentration of 0.5 mg/mL. Sonicate this dispersion for 2 hours to ensure uniformity.

- Form Cs-rGO Hydrogel: Mix 500 μL of the rGO dispersion with 1 mL of the Cs solution. Stir the mixture at 500 rpm for 12 hours. Electrostatic interactions between the cationic amino groups of Cs and the anionic rGO will facilitate the formation of a Cs-rGO hydrogel.

- Immobilize HRP Enzyme: Add 50 μL of 1% glutaraldehyde solution to 500 μL of the Cs-rGO hydrogel to act as a crosslinker. Then, incorporate the HRP enzyme into the mixture to form the final HRP/Cs-rGO biohydrogel.

Part B: Sensor Fabrication and Measurement

- Functionalize Microneedles: Coat the surface of the microneedle array with a thin gold layer using a sputtering system to create the working electrode.

- Apply Biohydrogel: Deposit the HRP/Cs-rGO biohydrogel onto the gold-coated microneedles, ensuring a uniform coating.

- Attach to Plant: Gently press the sensor against the underside of a plant leaf, allowing the microneedles to penetrate the tissue.

- Electrochemical Measurement: Connect the sensor to a portable potentiostat. Apply a suitable potential and use chronoamperometry to measure the current generated from the catalytic reaction between HRP and H₂O₂. The current is proportional to the H₂O₂ concentration.

- Data Analysis: Quantify H₂O₂ levels by comparing the measured current to a pre-established calibration curve.

Protocol: Visual H₂O₂ Detection using a Pt-Ni Hydrogel-Based Colorimetric Chip

This protocol describes the use of a dual-functional Pt-Ni hydrogel for simple, equipment-free visual detection of H₂O₂, suitable for field use [8].

Reagents and Materials

- Pt-Ni Hydrogel Chip: Synthesized via coreduction of chloroplatinic acid and nickel chloride with sodium borohydride (NaBH₄) [8].

- TMB Solution: (3,3',5,5'-Tetramethylbenzidine), chromogenic substrate.

- H₂O₂ Standards: Solutions of known concentration for calibration.

Step-by-Step Procedure

- Chip Preparation: Fabricate the sensing chip by depositing the synthesized Pt-Ni hydrogel onto a suitable substrate, such as a paper strip or plastic chip.

- Sample Application: Apply a liquid sample (e.g., extracted leaf sap or buffer solution containing H₂O₂) directly onto the Pt-Ni hydrogel chip.

- Colorimetric Reaction: Immediately after the sample, add a droplet of TMB solution. The Pt-Ni hydrogel exhibits excellent peroxidase-like activity, catalyzing the oxidation of TMB in the presence of H₂O₂.

- Incubation and Reading: Allow the reaction to proceed for approximately 3 minutes. The formation of a blue color (ox-TMB) indicates the presence of H₂O₂.

- Quantification: Perform semi-quantitative analysis by comparing the blue intensity to a reference chart. For more precise results, use a portable smartphone scanner or spectrophotometer to measure the absorbance at 652 nm.

Signaling Pathways and Experimental Workflows

The following diagrams illustrate the core biochemical signaling pathway for H₂O₂ in plant stress and the general workflow for using the described sensors.

Plant H₂O₂ Stress Signaling Pathway

Diagram 1: H₂O₂ in Plant Stress Signaling. This diagram shows how environmental stresses activate NADPH oxidase enzymes in plant cells, leading to a burst of H₂O₂ production. This H₂O₂ acts as a critical early stress signal that triggers the plant's systemic defense responses.

General Workflow for Portable H₂O₂ Sensing

Diagram 2: Portable H₂O₂ Sensor Workflow. The general workflow involves fabricating a base sensor (e.g., microneedle array or chip), functionalizing it with a sensing material (e.g., biohydrogel or Pt-Ni hydrogel), deploying it on the plant, transducing the H₂O₂ concentration into a measurable signal (electrical or color change), and finally, reading the data.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Portable H₂O₂ Sensor Development and Application

| Reagent/Material | Function in Experiment | Examples/Specifications |

|---|---|---|

| Horseradish Peroxidase (HRP) | Biological recognition element; catalyzes H₂O₂ reduction, generating an electrochemical signal or driving a colorimetric reaction. | Immobilized in Cs-rGO biohydrogel [30] or in BSA-based photonic crystal hydrogels [34]. |

| Nanozymes (e.g., Pt-Ni Hydrogel) | Synthetic enzyme mimics; provide superior stability and catalytic activity for H₂O₂ decomposition, enabling TMB oxidation for colorimetric detection. | Pt-Ni alloyed nanowires with Ni(OH)₂ nanosheets [8]. |

| Chitosan (Cs) | Natural biopolymer; forms a biocompatible and hydrophilic hydrogel matrix that facilitates enzyme immobilization and enhances sensor stability. | Used to form a Cs-rGO composite with reduced graphene oxide [30]. |

| Reduced Graphene Oxide (rGO) | Conductive nanomaterial; enhances electron transfer in electrochemical sensors, improving sensitivity. Prevents agglomeration when combined with chitosan. | Incorporated into Cs-rGO biohydrogel on microneedles [30]. |

| 3,3',5,5'-Tetramethylbenzidine (TMB) | Chromogenic substrate; undergoes a color change from colorless to blue upon oxidation by H₂O₂ in the presence of a peroxidase (HRP or nanozyme). | Used for visual detection with Pt-Ni hydrogel chips [8]. |

| Screen-Printed Electrodes (SPE) | Low-cost, disposable, three-electrode cell; serves as the platform for constructing portable electrochemical sensors. | Integrated with hollow microneedle arrays for fluid analysis [31]. |

Step-by-Step Protocol for Plant Sample Collection and Preparation

This application note provides a detailed protocol for the collection and preparation of plant samples, specifically tailored for the portable visual detection of hydrogen peroxide (H₂O₂). The accumulation of H₂O₂ is a key signaling event in plant responses to abiotic and biotic stresses [35]. The protocol centers on the 3,3'-Diaminobenzidine (DAB) staining method, which allows for the in situ detection of H₂O₂ as a dark brown precipitate [35]. Proper sample collection and preparation are critical for obtaining accurate, reproducible, and biologically meaningful results in visual detection assays.

Principles of Hydrogen Peroxide Detection in Plant Tissues

Hydrogen peroxide, a reactive oxygen species (ROS), is an incompletely reduced metabolite of oxygen with diverse physiological and pathological effects within living cells [36]. Its functions are highly dependent on the extent, timing, and location of its production. Visual detection methods, such as the DAB stain, exploit chemical reactions that produce a visible, localized color change upon oxidation by H₂O₂. In the presence of plant peroxidases, DAB is oxidized by H₂O₂, generating an insoluble, dark brown polymer that precipitates at the site of H₂O₂ accumulation [35]. This makes it an excellent tool for visualizing spatial patterns of H₂O₂ production in plant tissues during stress responses.

Materials and Reagents

Research Reagent Solutions

The following table details the essential reagents required for the DAB staining protocol.

Table 1: Key Research Reagent Solutions for DAB Staining

| Reagent/Material | Function/Application | Specifications/Notes |

|---|---|---|

| DAB (3,3'-Diaminobenzidine) | Chromogenic substrate that is oxidized by H₂O₂ to form a brown precipitate. | Use non-acidified powder (e.g., Sigma-Aldrich, D8001). The solution is light-sensitive and must be prepared fresh on the day of use [35]. |

| Tween 20 | Surfactant that reduces the surface tension of the staining solution, improving leaf wettability and infiltration. | Used at 0.05% (v/v). Ensures the solution makes uniform contact with hydrophobic leaf surfaces [35]. |

| Sodium Phosphate Buffer (Na₂HPO₄) | Provides a stable pH environment for the peroxidase-catalyzed oxidation reaction. | A 200 mM stock is used to prepare a 10 mM final concentration staining solution, which helps to pull the pH to an optimal level after initial acidification [35]. |

| Bleaching Solution | Clears chlorophyll from the leaf tissue to visualize the DAB precipitate against a clear background. | Composition: Ethanol : Acetic Acid : Glycerol = 3:1:1. The glycerol helps prevent the tissue from becoming brittle [35]. |

| Hydrochloric Acid (HCl) | Used to initially acidify the DAB solution to dissolve the powder. | A 0.2 M solution is used to carefully lower the pH to 3.0 to solubilize DAB [35]. |

Equipment

- Arabidopsis growth chamber or appropriate plant growth facilities

- Magnetic stirrer and stirring bar

- pH meter

- 1 ml needleless syringes (for infiltration of elicitors)

- 12-well microtiter plate

- Dessicator (for vacuum infiltration)

- Laboratory shaker

- Water bath or heating block (capable of maintaining ~90-95°C)

- 50 ml Falcon tubes [35]

Experimental Protocol: DAB Staining for H₂O₂ Detection

The following diagram illustrates the complete experimental workflow from plant growth to final visualization.

Detailed Step-by-Step Procedure

A. Preparation of DAB Staining Solution (Perform on Day of Use)

- Weigh and Mix: In a 50 ml Falcon tube, add 50 mg of DAB powder to 45 ml of sterile water for a final concentration of 1 mg/ml [35].

- Acidify to Dissolve: Add a small magnetic stirrer and slowly reduce the pH to 3.0 using 0.2 M HCl with continuous stirring. This step is crucial for dissolving the DAB.

- Protect from Light: Cover the tube with aluminum foil, as DAB is light-sensitive.

- Finalize Solution: Add 25 μl of Tween 20 (0.05% v/v) and 2.5 ml of 200 mM Na₂HPO₄ to the stirring DAB solution. This will result in a final 10 mM Na₂HPO₄ DAB staining solution and pull the pH back to a suitable range for the reaction.

- Note: The solution may not become perfectly clear, but a high degree of homogeneity is sufficient. The solution is only stable for the day [35].

B. Staining Leaves with DAB Solution

- Plant Material: Grow Arabidopsis plants under controlled conditions. Just prior to bolting (typically 3-4 weeks), select mature rosette leaves for consistency [35].

- Apply Treatment: Apply the chosen experimental treatment (e.g., wounding, pathogen infection, or abiotic stress). As an example, for a biotic stress response, infiltrate a leaf with 100 μl of a microbial elicitor solution (e.g., 0.5 μM Flg22) using a needleless syringe [35].

- Incubate Plants: Allow the plants to incubate for the desired time post-treatment (e.g., 1 hour for early Flg22 responses) [35].

- Sample Leaves: Manually remove the treated leaves and place them in a 12-well microtiter plate. It is acceptable to place 2-3 leaves in one well.

- Apply Staining Solution: Add 2 ml of the freshly prepared DAB staining solution to each well, ensuring leaves are fully immersed. For control treatments, use 2 ml of 10 mM Na₂HPO₄ solution without DAB.

- Vacuum Infiltrate: Place the 12-well plate in a dessicator and apply a gentle vacuum for 5 minutes. This critical step forces the solution into the air spaces within the leaf, ensuring uniform contact with the tissue.

- Shake and Incubate: Cover the plate with foil and place it on a laboratory shaker at 80-100 rpm for 4-5 hours. This incubation time can be extended (e.g., up to 8 hours) for systems with lower H₂O₂ production [35].

- Bleach Chlorophyll:

- After incubation, carefully remove the DAB staining solution and replace it with bleaching solution (ethanol:acetic acid:glycerol = 3:1:1).

- Place the sealed plate carefully in a boiling water bath (~90-95°C) for 15 minutes (±5 minutes). Monitor until the leaves are completely devoid of green chlorophyll.

- Replace the used bleaching solution with fresh solution and allow the leaves to stand for 30 minutes.

- Store and Image: The destained leaves can be stored in bleaching solution at 4°C for up to 4 days. For visualization, place leaves on a plain white background under uniform lighting and photograph [35].

Experimental Design and Best Practices

- Controls and Replication: Always include appropriate controls, such as untreated leaves and leaves stained with buffer alone. Sample at least 3 leaves per plant from 6 independent biological replicates. It is good practice to repeat the entire experiment at least once to ensure robust data [35].

- Considerations for Fluorescence Imaging: If further imaging of fluorescent probes is required, note that plant specimens present unique challenges, including strong autofluorescence, waxy cuticles, and air spaces. Best practices include [37]:

- Pilot Experiments: Perform a small pilot project to optimize imaging parameters.

- Platform Selection: Choose the appropriate microscope (e.g., widefield for thin samples, confocal for thicker samples requiring optical sectioning).

- Sample Preparation: Ensure samples are prepared to minimize background autofluorescence and are compatible with live or fixed imaging requirements.

Data Interpretation and Troubleshooting

Quantitative Reference Data

The table below provides expected results and key parameters for the DAB staining protocol under different experimental conditions.

Table 2: Expected Staining Outcomes and Key Experimental Parameters

| Experimental Condition | Expected DAB Staining Result | Optimal Incubation Time | Critical Step |

|---|---|---|---|

| Biotic Stress (e.g., Flg22 elicitor) | Strong, localized brown precipitate at infection sites or infiltrated areas [35]. | 4 hours [35] | Successful vacuum infiltration of the DAB solution. |

| Abiotic Stress (e.g., Drought, Cold) | Variable staining intensity and pattern, often dependent on stress severity and duration. | 4-8 hours [35] | Use of mature, uniform leaves for biological replicates. |

| Untreated Control Leaves | No or very faint background staining. | 4 hours [35] | Preparation of fresh DAB solution and effective chlorophyll bleaching. |

Troubleshooting Common Issues

- No Staining: Check the pH of the DAB staining solution and ensure it was prepared fresh. Verify that the vacuum infiltration was successful and that the leaves are not overly senescent.

- High Uniform Background Staining: This may indicate non-specific oxidation or cell damage during sample handling. Ensure leaves are healthy and not physically damaged during collection. Optimize the concentration of DAB and the incubation time.

- Incomplete Chlorophyll Removal: Extend the boiling time in bleaching solution in 5-minute increments, ensuring the solution remains hot. Prepare fresh bleaching solution if needed.

- Poor Image Contrast: After bleaching, ensure the DAB precipitate appears as a dark brown against a pale yellow or white background. Use uniform, diffuse lighting and a neutral background for photography [35]. For all image presentation, ensure sufficient color contrast between the precipitate and background for clear interpretation [38].

In the field of portable visual detection of hydrogen peroxide (H₂O₂) in plant samples, sample preparation is a critical foundational step that directly impacts the accuracy, reliability, and reproducibility of research findings. The choice between frozen and non-frozen processing techniques presents a significant methodological crossroad, each path leading to distinct consequences for sample integrity and analytical outcome. Within the context of a broader thesis on portable H₂O₂ detection, this document provides detailed application notes and protocols to guide researchers and drug development professionals in selecting and optimizing sample preservation methods. Proper preservation is paramount, as it maintains the native state of reactive oxygen species like H₂O₂, which are key signaling molecules and stress indicators in plant biology [39].

Section 1: Core Principles of Sample Preservation

The fundamental goal of sample preservation is to maintain the chemical and structural integrity of the sample from the moment of collection until analysis. For H₂O₂, a highly reactive molecule, this is particularly crucial.

Frozen Preservation: This approach aims to arrest all metabolic and chemical activity rapidly. The instant reduction in temperature slows down reaction kinetics, preserving the snapshot of H₂O₂ concentration and distribution at the moment of freezing. The success of this method hinges on rapid cooling to form amorphous ice (vitrification), preventing the formation of destructive ice crystals that can rupture cell membranes and cause leakage or redistribution of analytes [40].

Non-Frozen (Chemical) Preservation: This method uses chemical fixatives to cross-link proteins and stabilize cellular structures. While effective for maintaining morphology, it can introduce artifacts. The chemical agents may react with or alter the very molecules being studied, such as H₂O₂, potentially leading to inaccurate measurements [41].

Table 1: Comparison of Frozen vs. Non-Frozen Preservation Techniques

| Feature | Frozen Preservation | Non-Frozen (Chemical) Preservation |

|---|---|---|

| Primary Mechanism | Halting metabolic activity via rapid temperature reduction [40] | Structural stabilization via chemical cross-linking [41] |

| Impact on H₂O₂ Integrity | High potential for preservation if ice crystal damage is avoided | Risk of alteration or reaction with fixative chemicals |

| Cellular Morphology | Excellent preservation with optimized protocols (e.g., HPF) [40] | Good general preservation |

| Technical Complexity | High (requires specialized equipment like AFU, HPF) [40] | Low to Moderate (standard laboratory equipment) |

| Suitability for Portable Workflows | Low (requires a cold chain) | High (fixed samples are stable at room temperature) |

Section 2: Detailed Experimental Protocols

Protocol 2.1: Controlled Freezing for High-Resolution Analysis

This protocol, adapted from published methodologies [40], is designed for preserving plant samples where ultrastructural detail and accurate H₂O₂ localization are critical, prior to analyses like electron microscopy or high-resolution mass spectrometry imaging.

Materials:

- Automatic Freezing Unit (AFU) or controlled-rate freezer

- Liquid nitrogen

- Isopentane (pre-cooled by liquid nitrogen)

- High-Pressure Freezer (HPF)

- Specimen carriers

Procedure:

- Sample Preparation: Excise plant tissue rapidly and place on a prepared substrate (e.g., a cleaned silicon wafer).

- Controlled Freezing:

- Place the sample in the AFU, starting at a temperature between 0°C and +4°C.

- Initiate a controlled cooling ramp down to the target freezing temperature (e.g., -2°C to -6°C, depending on the plant species and experimental needs). Monitor temperature to ensure deviations are minimal (e.g., < ±1°C) [40].

- Transfer for Cryo-Fixation:

- Under a dry nitrogen atmosphere, immerse the sample in pre-cooled isopentane coolant for rapid freezing [41].

- Transfer the frozen sample to a pre-cooled metallic transfer block to maintain the cold chain.

- Quickly move the sample from the transfer block to the HPF device. The use of a precooling device is critical to prevent a temperature rise of more than ~1°C during this transfer [40].

- High-Pressure Freezing: Immediately load the sample into the HPF and initiate the freeze cycle. The high pressure facilitates vitrification, preserving cellular ultrastructure.

- Storage or Further Processing: The vitrified samples can be stored under liquid nitrogen or processed further through freeze-drying or cryo-substitution for specific analytical endpoints.

Protocol 2.2: Freeze-Drying (Lyophilization) for Mass Spectrometry Imaging

Freeze-drying is a common method for preparing samples for vacuum-based techniques like Time-of-Flight Secondary Ion Mass Spectrometry (ToF-SIMS), which can be used for spatial mapping of molecules, including H₂O₂-related metabolites, in single plant cells [41].

Materials:

- Freeze-dryer (e.g., Christ, Alpha 1-4 LSCbasic)

- Liquid nitrogen

- Vacuum desiccator (optional, for contamination control)

Procedure:

- Rapid Freezing: Following initial freezing as in Protocol 2.1 (Step 2), ensure samples are fully frozen.

- Primary Drying:

- Transfer frozen samples to the freeze-dryer pre-cooled to -55°C.

- Apply a vacuum of 10⁻³ mbar for approximately 12 hours to allow for sublimation of ice.

- Secondary Drying:

- Gradually increase the temperature to ambient conditions to remove any residual water or solvents (e.g., isopentane) without causing sample collapse.

- Post-Processing: The desiccated sample is now ready for analysis by ToF-SIMS or other techniques [41].

Protocol 2.3: Chemical Fixation for Morphology and Portable Assays

This method is suitable for workflows where immediate freezing is not possible, particularly when samples are to be used with portable colorimetric or electrochemical H₂O₂ sensors in the field or lab.

Materials:

- Glutaraldehyde solution

- Phosphate-Buffered Saline (PBS)

- Ammonium Formate (AF) solution (0.15 M)

- Ultrapure water

Procedure:

- Washing: Immediately after excision, immerse the plant sample in PBS for 2-3 seconds to remove surface contaminants. Repeat twice.

- Fixation:

- Transfer the sample to a glutaraldehyde solution for 15 minutes. This cross-links proteins and stabilizes cellular structures.

- Rinsing:

- Rapidly rinse the sample with a 0.15 M AF solution to remove salts from the PBS.

- Perform a quick rinse in ultrapure water.

- Drying: Air-dry the sample at room temperature [41]. The fixed sample is now stable and can be transported or stored for analysis with portable detection kits.

Section 3: The Scientist's Toolkit

Table 2: Essential Research Reagent Solutions for H₂O₂ Sample Preparation and Detection

| Item | Function/Application |

|---|---|

| Glutaraldehyde | A cross-linking fixative for non-frozen, chemical preservation of cellular morphology [41]. |

| Ammonium Formate (AF) | A volatile salt used in washing steps to remove non-volatile salts that can interfere with mass spectrometry analysis [41]. |

| CHEMetrics H₂O₂ Self-filling Ampoules | Simple, snap-and-read ampoules for visual or photometric quantification of H₂O₂ residuals, useful in validating sterilization or rinsing steps [42]. |

| Pt-Ni Hydrogel-based Sensors | Nanozymes with excellent peroxidase-like activity for portable colorimetric or electrochemical H₂O₂ detection in complex samples like cell culture media [8]. |

| Hydrogen Peroxide Colorimetric Assay Kit | Kit based on the reaction of H₂O₂ with ammonium molybdate to form a yellow complex, quantifiable at 405 nm; suitable for various sample homogenates [43]. |

| Hydrogen Peroxide Fluorescent Detection Kit | A highly sensitive (0.038 µM) kit for quantifying H₂O₂ in urine, buffer, and tissue culture media using a fluorescent readout [44]. |

| Osmium-Horseradish Peroxidase (Os-HRP) Electrode | A mediator in a catalytic amperometric biosensor for real-time, sensitive electrochemical detection of H₂O₂ in sub-cellular plant structures like PSII membranes [39]. |

Section 4: Workflow and Pathway Visualizations

Sample Preservation Workflow

H2O2 Detection Pathways

Section 5: Application Notes and Concluding Recommendations

The choice between frozen and non-frozen techniques is not merely procedural but strategic, dictated by the final analytical goal.

For High-Resolution Spatial Mapping: If the research objective is to understand the sub-cellular localization of H₂O₂ production or its effects on ultrastructure, such as in chloroplasts or mitochondria, frozen preservation via controlled freezing and HPF is the gold standard. This approach, despite its technical demands, provides unparalleled structural preservation, minimizing artifacts and providing confidence in the spatial data obtained [40].

For Portable Field Analysis and Quantification: When the primary need is for rapid, in-situ quantification of H₂O₂ levels, particularly in resource-limited or field settings, chemical fixation followed by portable sensor kits is highly effective. The stability of fixed samples and the simplicity of colorimetric strips [42] or portable electrochemical sensors [8] make this workflow highly practical.

For Mass Spectrometry Imaging: For techniques like ToF-SIMS, which require a vacuum and are sensitive to surface contaminants, freeze-drying is a robust and convenient method. The protocol prevents the introduction of extraneous signals and ensures the molecular integrity required for reproducible single-cell metabolomic profiling [41].

In conclusion, optimizing sample preservation is the first and most critical step in ensuring the validity of data in portable H₂O₂ detection research. By aligning the preservation strategy with the analytical endpoint—whether it is ultrastructural analysis, spatial metabolomics, or field-based quantification—researchers can ensure that their results truly reflect the biological reality of the plant system under investigation.

Field Deployment Strategies for Real-Time Plant Stress Monitoring

Real-time monitoring of plant stress is pivotal for advancing precision agriculture, enabling early disease diagnosis, and improving crop resilience. Hydrogen peroxide (H₂O₂) has been established as a key signaling molecule in plant stress responses, with its dynamic fluctuations providing one of the earliest indicators of both biotic and abiotic stresses [14] [45]. The development of portable, visual detection methods for H₂O₂ allows researchers to decode these early stress signatures directly in the field, shifting from reactive to proactive crop management. This document outlines field deployment strategies and detailed protocols for monitoring plant stress through portable H₂O₂ detection, framed within a broader research context of developing accessible analytical tools for agricultural scientists.

Sensor Technologies and Performance Data

Various sensing platforms have been engineered for the detection of H₂O₂ in plants, each with distinct operational principles, advantages, and performance characteristics suitable for field deployment. The selection of an appropriate sensor is critical and depends on the required sensitivity, the need for quantification versus spatial mapping, and the specific environmental constraints of the application.

Table 1: Performance Comparison of Portable H₂O₂ Sensors for Plant Monitoring

| Sensor Technology | Detection Mechanism | Detection Limit | Linear Range | Response Time | Key Advantages |

|---|---|---|---|---|---|